Warehousing is the act of storing goods that will be sold or distributed later. While inventory control refers to “all aspects of managing a company’s inventories like purchasing, shipping, receiving, tracking, warehousing and storage, turnover and reordering.” Inventory control is also important to maintaining the right balance of stock in your warehouse. Warehousing and inventory control systems help a business monitor and track the amount of raw materials, finished goods and work in the process the company always has on hand.

Table of Contents

ABC Inventory Analysis

The ABC analysis is a popular inventory categorization method/technique that often used in material management and Inventory control. ABC analysis provides a mechanism for identifying items that will have a significant impact on an overall inventory cost and it also helps to identify different categories of stock that will require different management and controls.

ABC analysis divides the inventory into three categories. “A” item is very important or being the most valuable items for an organization, “B” item is important but of course less important than “A” or being the intergroup item, “C” marginal important or the least valuables item. By knowing the important and values it helps warehouse to reduce the time to allocate and put-away.

ABC Analysis is also similar to the Pareto principle. Below is an example.

“A” items – 20% of the items account for 70% of the annual consumption value

“B” items – 30% of the items account for 25% of the annual consumption value

“C” items – 50% of the items account for 5% of the annual consumption value

Economic Order Quantity (EOQ)

Economic order quantity (EOQ) is a procedure to determine the ideal order quantity level for stock to be ordered at a particular time. It also a formula that used to determine the most efficient amount of goods that should be order and carrying cost may be reduced to a minimum point. A firm should place optimum orders and neither too large nor to small. The EOQ is level of inventory order that avoid stock-out and overstock and minimizes the total holding costs and ordering costs.

Economic order quantity (EOQ) is a decision tool used in cost accounting. It is a formula that allows you to calculate the reorder point, which is a level of inventory for a given products that triggers the need to place an order for more inventory. Thru the reorder point, organization can avoid running out of inventory and able to fulfill all customer orders. EOQ assumes that you order the same quantity at each reorder point.

The EOQ model is a very simple one and its assumptions will be unrealistic in many applications, in practice orders are not delivered instantly. The assumption of constant usage of inventory and known annual demand are of doubtful validity.

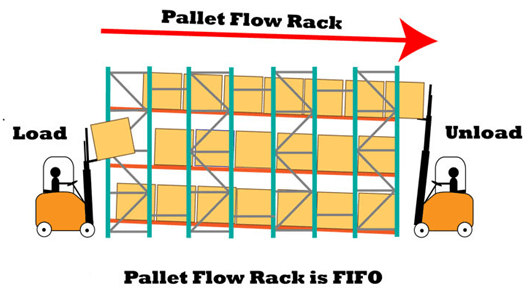

First-in-first-out (FIFO)

The first in, first out (FIFO) method of inventory valuation is a cost flow assumption that the first goods purchased are also the first goods sold. A simple principle, yet vitally important to mention – especially if dealing with perishable items. For most retailers, the last thing you want is always using the newest stock to fulfil orders. This leaves older inventory sitting in the warehouse and susceptible to damage, decay or passing best before dates. It’s worth making a rule to store new inventory from the back of shelves and then take from the front – automatically enforcing a FIFO system.

Last-in-first-out (LIFO) is a newer inventory cost valuation technique, which assumes that the newest inventory is sold first. LIFO gives a higher cost to inventory. The difference between FIFO and LIFO results from the order in which changing unit costs are removed from inventory and become the cost of goods sold. When the unit costs have increased, LIFO will result in a larger cost of goods sold and a smaller ending inventory compared with FIFO.

Also, note that the order in which the costs are removed from inventory is independent of the order in which the physical units are removed from inventory.

| Advantage (FIFO) | Disadvantage (FIFO) |

| Less likely to be subject to management manipulation | Bad matched of sales revenue and CGS; match current sales revenue with old cost |

| Produce higher income during an inflation period | Producing higher income during an inflation period results in paying more income tax. |

| Inventory cost reported on the B/S is close to the replacement cost. |

Just in Time (JIT)

The JIT inventory control technique says that the item will be ordered only if it is needed for shipping or manufacturing. Most of the company use this technique to increase efficiency and decrease waste by receiving goods only as they need. The item may be ordered a few days back depending on the delivery time promised by the supplier. A mandatory requirement of this approach is the proper identification of each item before the manufacturer or reseller requires it. Since there can be many goods required by supplier or manufacturer at any time, each future requirement should be properly identified and timely ordered.

Another crucial requirement for this technique is the timely delivery of the order by the supplier. Since the item is ordered just before it is needed, any delay in the arrival of the item may delay the whole production/shipping process; this may be treated as a drawback in the approach. The JIT inventory management technique helps reduce the size of the inventory and leads to low storage costs. Although, early identification and order of all items required in the future should always be there to make this approach effective.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Daniel Fritsch (2015). “6 Inventory Control Techniques for Stock Optimization”. Retrieved from https://www.eazystock.com/blog/2015/08/03/6-inventory-control-techniques-for-stock-optimization, accessed 18/12/2018.

Laran Joseph (2014). “Inventory management Techniques and Their Importance. Retrieved from https://blog.udemy.com/inventory-management-techniques, accessed 18 Dec 2018.

Mike Glover. (2017). “Inventory Control Methods”. Retrieved from https://www.veeqo.com/blog/inventory-control-methods, accessed 01/12/2018.

Terese Ong Yee Chiat, DLSM. (2018). “Five Important Techniques for effective inventory control”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/five-important-techniques-for-effective-inventory-control, accessed 18/12/2018.

Veron Wong Sook Wei, DPSM. (2018). “Effective Techniques for Inventory Stock Control”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/effective-techniques-inventory-stock-control, accessed 18/12/2018.