Warehouses play a very important role in supply chains to meet the productivity goals. A good warehouse operation can impact a lot from practical factors like delivery, to a company’s year-end profitability, customer satisfaction etc. For example, implement WMS (Warehouse Management System) brings efficiency, consistency and quality control to the process by improving every stage of the fulfilment process. Therefore, looking at the long-term growth needs, business need to identify key considerations for effective warehouse operations.

Table of Contents

Designing a Good Warehouse Layout

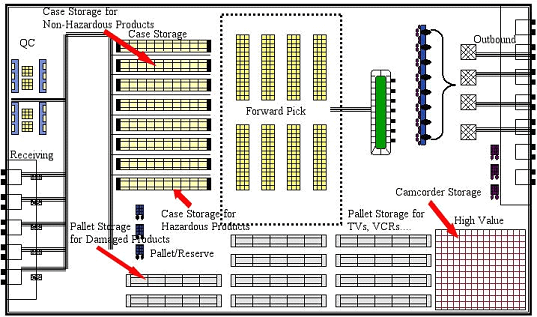

A practical warehouse layout is an important process because it will direct impact on the efficiency and productivity of warehouse. The planned layout should arrange a logical process flow that can help to streamline operations, boost up productivity, and reduce overhead expenses. A good warehouse layout design can store goods easily, shorten staffs travel time within warehouse, improve order fulfilment rates.

Additionally, it is very important to identify all the necessary requirements the during the layout planning phase. Once the construction starts, any changes to the planned layout is costly because it may involve additional material and labour costs.

There are some key factors to design an ideal warehouse layout. Firstly, a company will need to think of budget considerations to confirm enough budget that will facilitate the construction from the foundation up to roofing. If the warehouse layout achieved optimum throughput, it will be a perfect warehouse layout design. Secondly, the warehouse layout whole space must be optimised and fulfil to the operation workflow. In addition, warehouse design layout needs to follow as per the government rules and regulations, warehouse safety is very important.

Choosing the Right Technology

Warehouses is a storage place to protect products and stock goods for future use. However, globalisation nowadays and internet evolution area pressure companies to provide more value-added services, better service level, cost effective and transactions traceability. If the company is not upgrading the warehouse service with technology, it will be not competitive in the market and among the competitors.

Implementing the warehouse management system (WMS) in the warehouse can help to control and manage the daily warehouse operation. Warehouse can minimize the human errors and paperless to perform inventory receiving and put-away, optimizes picking and shipping of orders and inventory replenishment by using WMS. By using WMS system like RFID (Radio-frequency Identification) can read multiples tags at the same time, it saved warehouse operation time to scan carton by carton. WMS system increase efficiency in warehouse operations which is the important factor to keep the company’s KPI and more competitive among competitors. The benefits of a comprehensive WMS are reduced fulfilment time, increased inventory accuracy, improved customer service level, greater space utilization, increased warehouse productivity and reduced labour cost.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.