There are thousands of warehouses across the nation and each one can offer you different services and storage needs depending on the type of goods you import or sell.Some of the biggest warehouses are able to provide every type of specialist storage available, while others will focus on just one or two.

Table of Contents

Ambient Storage

Ambient storage refers to warehouse that store goods not needing temperature control, often what most people refer to as ‘room temperature’ which is what would normally be considered comfortable. Most products, other than certain foods and perishables would require ambient warehousing. Which warehouses have a number of ambient storage partners throughout the whole of the UK who can assist with this type of storage and handling.

Cold Storage

Cold and chilled storage in warehouses is used mainly for storing fresh food and other perishables as it slows down and can even stop damage from insects and bacteria, which will ruin these types of products if left at room temperature.Other products, such as freshly cut flowers, can also be stored in chilled storage, as this keeps them in top condition for moving forwards in the supply chain.

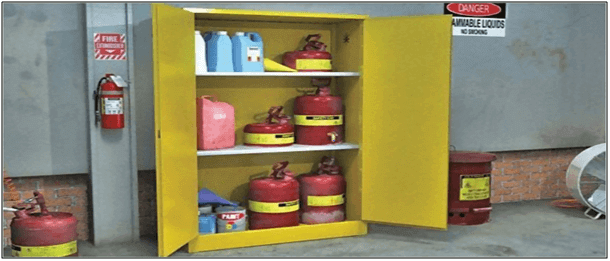

Hazardous Storage

Hazardous storage can vary depending on what dangerous materials a warehouse is handling. Flammable liquids, chemicals and other such materials are usually kept in specially designed storage units that are locked for extra security. Gas based items, such as oxygen tanks or propane cylinders are usually stored in large cages to prevent being knocked over or damaged. When looking for hazardous storage the class of the hazardous goods would be needed as warehouses work with varying classes of hazardous goods and just because a warehouse advertises as a hazardous warehouse they may not be able to accommodate your type of goods due to their licensing.

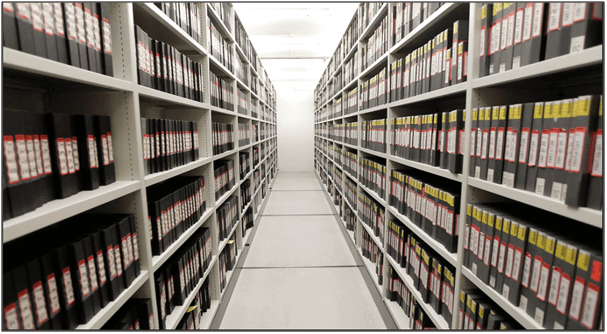

Archive Storage

Important documents and data that no longer need to be stored onsite at a company can be kept in archive storage in a warehouse. This is particularly good for companies who handle lots of information on a daily basis as space can fill up quickly such as solicitors.

Identifying the optimal storage location for goods

The better the way in which the various goods are stored, the more efficiently their retrieval can be managed. This also brings about improvements in terms of:

o Retrieval times

o Picking accuracy

o Work processes

o Search times

To find the optimal position for each individual product within the warehouse, further data is required in addition to information about the goods (size, weight, etc.):

o Retrieval frequency

o Number of retrieved units in each case

o Number of units to be stored

o Product-specific storage requirements

o Turnaround frequency

WMS then allocate the optimal location to the goods based on this data.

Maximize All Available Space

Maximizing warehouse space can be achieved by raising its roof. Where real estate is too costly to consider expansion, an option gaining additional space, improving the height of your warehouse space can do good. This can give space for additional levels of pallet storage. The things to be taken into consideration before going for raising the roof. Consider the engineering limitations and building codes so that your additional height doesn’t become illegal.

Storage Space Adaptation

With this approach, the storage spaces are filled with goods according to their capacity to hold them. Small spaces are occupied by low-volume storage units and low stock levels, while larger areas are correspondingly filled with larger goods or units with high stock levels.

Pallet racking system

Racking and pallet storage serve as another vital method of warehouse space optimization. After ensuring you take all necessary safety factors into account, you should create a warehouse layout and design that fits your needs. Whether your company’s first install or a revamp of your entire system, there are many pallet rack systems to choose from to optimize your warehouse storage space.

Some of these include:

o Pushback pallet racking systems

o Drive-in pallet racking systems

o Pallet flow racking systems

o Carton flow racking systems

o Cantilever racking systems

Using pallets as load bearers and storage is an effective practice and can save your company thousands of dollars in real estate and storage space. It also will improve productivity and employee efficiency, as pallet racks make organizing and retrieving goods simple and fast.Warehouse management is ultimately an exercise in efficiency. A business’s facility operates at its best when errors are minimal, delays and disruptions are eliminated and productivity is maximized with a smooth flow of inbound and outbound activity.

The available space and physical characteristics

The available space and the infrastructure involved significantly influences the layout structure inside the warehouse. For instance, space will determine the design of the shelves, the installation required and the circulation of items in the warehouse. Other essential features to consider include access, floors, power lines, etc. Additionally, depending on jurisdiction, there are building regulations that might affect the design and structure of the warehouse.

Equipment involved

Regardless of the size or the intended purpose, a warehouse should contain elements such as forklifts, racks, and transport apparatus. The equipment involved influences the design of the warehouse. For example, you have to ensure the design will facilitate free movement of equipment inside the warehouse. Also, the layout should accommodate the integration of new equipment in the future in case of expansion. Operations and efficiency inside the warehouse largely depend on the layout and design. Therefore, the design of the warehouse contributes significantly to the supply chain process. Warehouses that have been carefully designed enable an organization to achieve maximum operations and improved productivity.

Conclusion

Choosing the right warehousing solution can help save money, meet demand, and drive efficiencies. Working with a third-party logistics company is very common for ecommerce businesses that don’t want to manage a warehouse themselves.There are various methods and careful planning needed during the period of strategies selection that are most suitable for your organization. Upon selection, implementation and changes are the most critical period as reluctance to change might occur within the organization and the warehouse. Organization need to embrace personalization and optimization to improve conversion, retention and average customer spend. By integrating optimization more tightly into the business strategy, organization will transform customer’s experiences and deliver additional revenues to the business.

References

Jonathan Goh, DLSM (2018). “Key Strategies to Improve Warehouse Space Efficiency”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-strategies-improve-warehouse-space-efficiency/, accessed 11/09/2019.

Kristina Lopienski. (2018). “What is Warehousing? ShipBob Guide to Warehousing Solutions and Logistics”. Retrieved from https://www.shipbob.com/blog/warehousing, accessed 14/09/2019.

Muhammad HairulBin Hassan, DLSM. (2018). “Effective Warehouse Storage for Shipment Efficiency”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/effective-warehouse-storage-for-shipment-efficiency/, accessed 14/09/2019.

Saras. (2018).“Understanding the Basics of Warehouse Layout Design”. Retrieved from http://www.readership.org/understanding-the-basics-of-warehouse-layout-design, accessed 14/09/2019.

Sarah Robey. (2014). “7 Different Types of Specialist Warehouse Storage”. Retrieved from: https://www.whichwarehouse.com/blog/news/7-types-specialist-warehouse-storage/, accessed 11/09/2019.