Successful procurement strategy benefits are usually derived from adequate and efficient procurement procedures that achieve cost optimizing that meet user requirement. Satisfactory procurement activities are resulted in three major advantages: (1) cost savings, (2) product effect, and (3) technology development commitment. Supplier partner management should be customized to those principles that are aligned with the overall strategy of business value. Relationship results may vary from cost savings to collaborative product development. Once the objective (output) has been determined, it is possible to develop the correct partnership.

For example, not all vendors should be treated in the same manner. Its technology allows sourcing executives to develop and implement a range of different supplier approaches. Therefore, effective procurement practices involve the choice of strategies which conform to the prevailing circumstances.

Table of Contents

Terminology of Procurement versus Purchasing

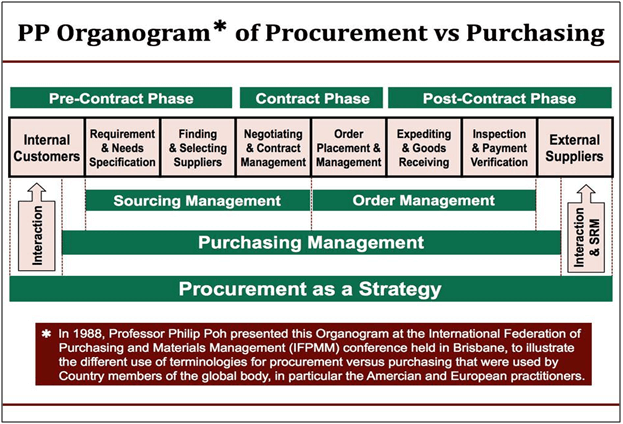

Procurement is often mistaken for purchasing, and the two terms are often used interchangeably. We need to understand clearly the difference between procurement and purchasing. Purchasing refers to the process of ordering and receiving goods and services. It is a part of the procurement process. Purchasing refers to the process involved in ordering goods such as request, approval, and the creation of a purchase order record and ultimately the receipt of goods.

On the other hand, “procurement” is the function that describes the activities and processes to acquire goods and services. The key difference can perhaps be explained from the PP Organogram, as shown in the diagram below. Procurement requires active engagement with internal customers, as well as with suppliers.

Pitfall of Poor Supplier Management

There are a few mistakes that may exist here. One of the most popular is to place too much financial pressure on the manufacturer by drying out in pursuit of bare minimum rates. While this may be a way to increase the side’s benefit, if allowed, this may create a standard that cannot always be fulfilled. Suppliers are also organizations and must be able to maintain the supply and demand of all the industries with which they operate. Purchasing requires finding the best deals, but in search of them, a pitfall can lie in deteriorating supplier relationships.

With that said, staying competitive is necessary. To order to avoid this pitfall, business should look further and focus on creating a long-term partnership relationship instead. For maximum benefits to create a long-lasting business partnership. This will help to ensure timely delivery, great deals, and therefore the best value for your money.

Although the price you pay might not be the lowest price in market, a strong supplier support will reap its reward in the future. But don’t think about competing for the best prices. Only make it known when to draw the line out of consideration for your friendship and company. There may be times when drastic actions such as altering existing contracts or replacing vendors is necessary and for the business’ best interest. However, much analysis weighing the pros and cons will be needed before coming into any conclusion. Yet realize it can impact the performance of the company.

Pitfall of Failing to Negotiate

While the problem of competition from vendors is one of bargaining breakdown, the procurement process is just as complicated. Suppliers are firms that can not necessarily tell a buyer of the best deal. Your acquisition officials should be diligent about pursuing arrangements and should not be reluctant to anticipate deals offered from alliances. Maximizing interest is critical for the company and it should be a standard operation procedure to compare prices especially for large purchases. client and never hurt asking. Pressure can only harm the connection between the manufacturer.

Procurement officers will try to monitor deals and negotiate better deals where possible in order to prevent this pitfall. This does not provide for extra sales for goods and services which can be diverted or used in another region. Ensured that the customer is fulfilled with both the manufacturer and the consumer in order to maintain a lasting relationship with the supplier.

Pitfall of Focusing Only on Price

Another downside of competitive procurement is that it moves the emphasis from just gazing at the initial purchase price to considering the total cost of owning or using a product or service. Many companies still practice receiving multiple quotations, but instead of always choosing based on lowest price, they take into consideration overall cost from buying to maintenance to disposal. Alternatively, they take into account many other factors that affect total ownership costs such as operating costs, recruitment, repairs, warehousing, etc. The total cost is always much more than you expect and much more than the seller can afford. It’s like buying a car and reselling it afterwards.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

AlexandraTwin. (2019). “Total Cost of Ownership (TCO)”.

Retrieved from https://www.investopedia.com/terms/t/totalcostofownership.asp, accessed 23/12/2019

Andrew Wong. (2018). “The ‘father of A.I’ urges humans not to fear the technology”.

Retrieved from https://www.cnbc.com/2018/05/16/jurgen-schmidhuber-urges-humans-not-to-fear-artificial-intelligence.html accessed 23/12/2019

Derrick Chevalier. (2019). “Three Reasons Why Negotiators Fail”.

Retrieved from https://www.negotiations.com/articles/negotiation-framework/, accessed 23/12/2019.

Tang Wei Wen, DPSM. (2018). “Key Challenges for Effective Procurement Negotiation”. Retrieved from https://publication.sipmm.edu.sg/key-challenges-effective-procurement-negotiation/, accessed 24/12/2019.

Wang Min, DPSM. (2017). “Importance of Effective Procurement Practices for Successful Hotel Operations”. Retrieved from https://publication.sipmm.edu.sg/importance-of-effective-procurement-practices-for-successful-hotel-operations, accessed 23/12/2019.