As the world market demand grows, be it in pharmaceutical, retail, food and beverage, or manufacturing, logistics and warehousing have always been one of the vital elements that help these sectors to function. It is imperative that companies have their warehouses equipped with the latest processes, trends, and technologies, in order to provide outstanding logistical service to their customers.

Smart warehousing means automating various components of warehousing operations. Increasing productivity and efficiency of the warehouse, minimizing the number of human workers while decreasing errors; which contributes to lower operating costs and may translate to lower prices for goods and services for consumers. Resulting in solutions that are more accurate and flexible for the employees to work around their capabilities. In this article, you will discover the smart technologies for efficient warehousing.

Table of Contents

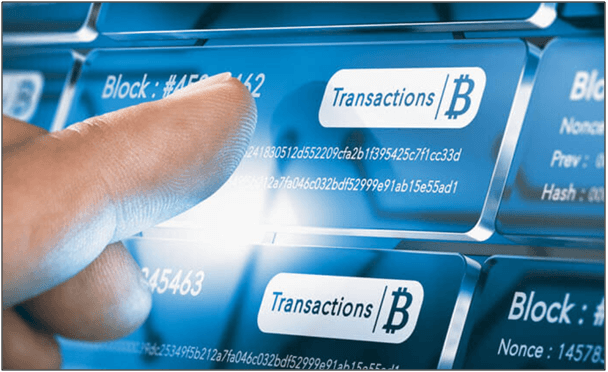

Blockchain Technology for Warehouses

Blockchain is a technology whereby information is synchronized and shared mutually across a network. This enables the secure exchange of record transactions between parties. Blockchain brings three key features – Security, Accountability, and Accessibility for everyone in the network.

The processes in a warehouse require a great effort to maintain. Some of which are record data and audits of damaged inventory, costs, stock ins and outs, discrepancies, and many more. Blockchain’s design allows every party to be connected to the manufacturers, brands, production sites, suppliers, and other vendors. This enables the network to manage and track product sources, traceability, perishables, and recalls. Thus, creating a broader warehouse management system on flawless track.

Through Blockchain, warehouses may utilize smart contracts to automate verifications and transactions. For instance, when certain goods are delivered, the proof of delivery will be reflected in the Blockchain system to be verified. After which, transactions will be made to the parties. This automation significantly increases security, integrity, and efficiency.

RFID Technology for Warehouse Operations

RFID leverages low-power radio frequencies in a warehouse or distribution centre to collect, automate and store data. Working hand-in-hand with a Warehouse Management System (WMS), RFID is an excellent real-time business tool that helps better manage supply chains, covers goods entry, picking, checking, delivery and many other operations flows, increases profit, and decreases the cost by improving visibility into the warehouse management system.

RFID offers many advantages over the standard barcode label. An RFID tag can hold much more data about an item than a barcode and are not susceptible to the damages that may be incurred by barcode labels, like ripping and smearing. RFID also provides quick access to the order database while providing on-the-spot visibility that is needed to cross-dock the incoming material for immediate shipping to fulfil customer orders.

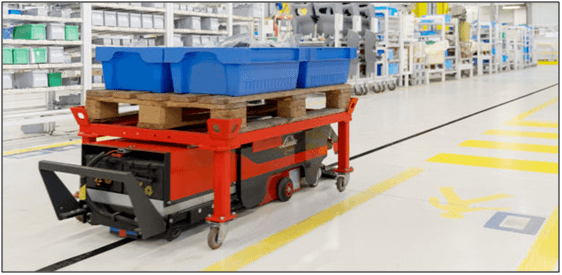

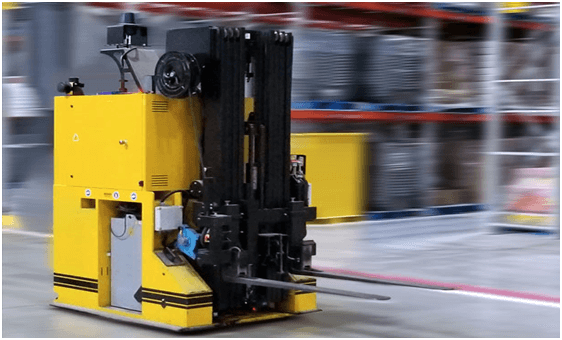

Automatic Guided Vehicles (AGVs)

AGVs are an integral part of warehouses. Compared to other forms of automation, they are quicker and come with a lower implementation cost. AGVs remove the human element in the process, allowing them to carry out their tasks autonomously. AGVs can be used for various tasks. From receiving at inbounds to order-picking to moving raw materials within the warehouse to the production lines. This includes palletizing, racking, and managing container storage. With AGVs in the warehouse, it provides workplace safety with lower costs, better inventory accuracy, and less expensive than fixed automation systems. There is also reduced labour cost and eliminates product and structure damages.

- Automated Guide Carts – They can transport a wide range of materials and are commonly used in cross-docking applications, sorting, and storage.

- Forklift AGV – Designed to carry out similar tasks as a human-operated forklift, without the need for a human operator.

Internet of Things (IoT) Applications

Internet of Things (IoT) are physical devices that are connected to the internet for sharing and collection of data. The availability of wireless networks and small-sized computer chips have made it possible for thousands of products to stay connected. IoT devices will be able to detect and monitor their environment and report their status, receive directions, and act on the information they receive.

- IoT-integrated management systems: Instead of gathering inventory data manually, warehouse professionals can outsource the task to a range of connected sensors or RFID tags. The data is then stored on a cloud-based platform that will be processed and analysed.

- Wearables: Connected devices will assist warehouse professionals to instantly identify products and packages. Wearables will track the accuracy of product picking to assessing the efficiency of corporate training and keeping track of employees’ individual performances.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Benjamin Then Chuang Soon, DLSM (2020). “Essential Technologies for Warehousing Productivity”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/essential-technologies-warehousing-productivity/, accessed 22/03/2021.

Chris Benevides. (2016 & 2021). “7 Cost-Saving Benefits of Automated Guided Vehicles (AGVs)”. Retrieved from: https://www.conveyco.com/7-cost-saving-benefits-automated-guided-vehicles-agvs/, accessed 22/03/2021.

Hunter Lowe. (2019). “Smart Warehousing: What are Smart Warehouse Systems?” Retrieved from https://www.selecthub.com/warehouse-management/smart-warehouse-systems/, accessed 22/03/2021.

Leong Jian Jie, ADLSM. (2019). “Key Digital Technologies for a Smart Warehouse”.Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-digital-technologies-smart-warehouse/, accessed 22/03/2021.

Megan Ray Nichols. (2019). “10 smart technologies you need to implement in your warehouse”. Retrieved from https://theiotmagazine.com/10-smart-technologies-you-need-to-implement-in-your-warehouse-2b2db57dbf01 , accessed 22/03/2021.

Mohd. Aktar, DLSM. (2019). “Key Factors to Consider for a Smart Warehouse”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-factors-consider-smart-warehouse/, accessed 28/03/2021.

Naresh Kumar, DLSM. (2019). “Digital Technology for Warehouse Productivity”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/digital-technology-warehouse-productivity/, accessed 22/03/2021.

WhatNext. (2020). “Drone Application for Warehouse Inventory Management” Retrieved from https://www.whatnextglobal.com/post/drone-application-for-warehouse-inventory-management, accessed 28/03/2021.