The Organization for Economic Cooperation and Development predicted that global demand for materials would increase by more than 35 percent over the next 15 years, reaching 100 billion metric tons per year. In 2019, Singaporeans threw out 930,000 tonnes of plastic, of which only 37,000 tonnes – or 4 percent – were recycled.At the current rate of waste disposal indicate that the Semakau landfill, the only landfill in Singapore could be full by 2035, a decade ahead of the initially projected 2045.

Landfills all over the world are reaching their maximum capacity. Therefore to prevent waste and promote sustainability, Companies need to take discarded materials or end-of-life products and remake or recycle them. They will want to go along the “take-use-recycling” instead of the “take-use-discard” production cycle.

Recycling extends the life cycle of products. Companies can harvest metal parts from discarded electronics such as mobile phones and computers. This will lead to more profits and less harm to the environment. It will need to be a joint effort by public, private sectors, consumers and above all, it will need innovation to make this a reality. The benefits of circular supply chain (CSC) which include but not limited to insights from customer, better product designs, economical in the long run, help the environment, help the companies to meet regulations and perhaps to obtain government grants as well.

Table of Contents

Reverse Logistics Supports CSC

For CSC to take place, there must be a logistics process for a takeback program. Companies will minimize the production of ‘new’ materials, as all end-of-life products should be recovered fully. The products can be refurbished and return to the market, breakdown easily into composite or recycled. It should not wind-up in the landfill. Reverse logistics will also lead to more business opportunities to increase revenue for companies. The visibility of the product is key in reverse logistics.

United Parcel Service (UPS) partners with Toshiba to repairs the latter’s damaged laptops. Toshiba’s customers can take damaged laptops to more than 3,300 UPS stores throughout the US, and UPS performs the entire reverse logistics and even the repair process. The laptops are shipped to a centralized location that is right beside UPS world air hub to be repaired and returned to the customers.

This partnership allows Toshiba and UPS to consolidate e-waste and accelerate its recycling. Toshiba’s customer satisfaction increases as their laptops are repaired faster and Toshiba can have product improvement through identifying faulty hardware components. UPS has another stream of revenue from repair and recycle materials. Most importantly, there is reduced transportation and fuel cost which will have a positive impact on our environment.

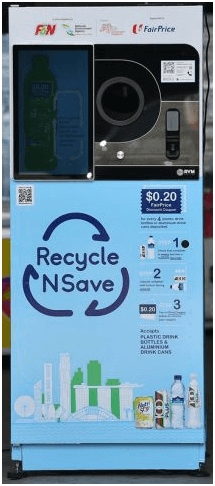

In Singapore, reverse vending machines as seen below are deployed in her city-state to encourage recycling. Consumers will be given a reward for depositing their used plastic drink bottles and aluminum cans. This deposit refund scheme is a feature of a programme that makes manufacturers of products responsible for the end-of-life collection and treatment of the items. It targets the management of electronic and packaging waste ultimately.

Product-As-A-Service Model

Due to fluctuating demand and unplanned downtime, companies can consider renting instead of purchasing their equipment for sustainable procurement practices. For example, they can lease vehicles.

Companies will only pay for the usage of the equipment. This will give companies better control over the total cost of ownership of equipment. This will free up their cash flow and can use their capital to invest in its core business that will generate a higher ROI. They can also lease equipment to match the life of a new work contract.

They do not need to commit to the import taxes and maintenance costs of the equipment. At the end of the lease contract, they can return the equipment and avoid all disposal costs. Thereafter, that equipment after refurbishment can be lease out again to another company hence, the life cycle of the equipment is extended.

Sustainable Materials for Packaging

Packaging is essential in the sales and delivery of physical products. Packaging protects the product while in transit, it provides the consumer with important information about the product and it can be part of the company’s branding as well.

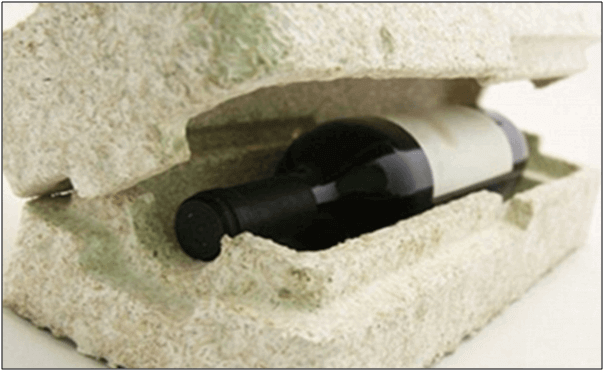

Companies that adopt CSC will want to procure and design packaging has been manufactured from sustainable materials using energy from renewable sources. The packaging ought to remain safe and effective throughout its life cycle, after which its component materials should be fully recyclable, thus creating a closed loop of manufacturing and usage. Examples include biodegradable packaging peanuts, corn-starch packaging, recycled cardboard and paper for their cartons boxes, bioplastic made from fish waste, seaweed packing, etc.Furniture giant, IKEA uses eco-friendly boxes made of mushrooms, as shown in the image below.

Packaging designs should be efficient for transportation by “cubing out”, the process of filing a shipping container to its most effective potential. It should be lightweight and compact as this will reduce the carbon footprint and reduce transportation cost.

Investing in Blockchain Technology

Digital Technologies enables CSC through enhancing connectivity and timely sharing of information across the manufacturing, distribution and consumer ecosystems during the products’ use phase and at their end-of-life phase.

An increasingly huge number of companies see that sustainability is important to success and more consumers are willing to pay for products that are produced ethically and sustainably. Through Blockchain technology, materials can be used to given a single digital identity hence increase consumers’ awareness and ability to make sustainable choices.

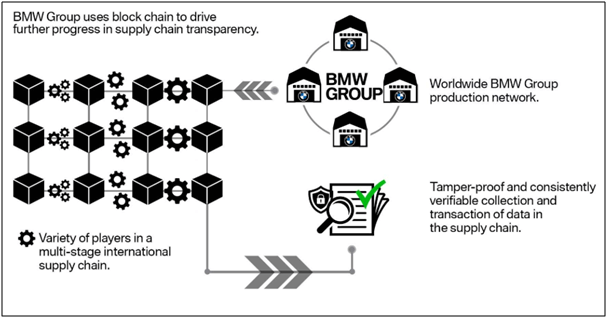

In the past, the BMW Group’s suppliers manage their data separately. Supplier’s IT systems have not always been able to communicate consistently with one another. Hence, ensuring transparency is an extensive manual effort for the Group’s purchasers and its suppliers.

Currently, the BMW Group uses Blockchain technology that allows tamper-proof data sharing with prospective applications throughout the whole automotive value chain. This also ensures the traceability of components, raw materials and spare parts in multi-level international supply chains. This also leads to a decrease in counterfeit automotive parts.

Blockchain technology rationalizes the supply chain workflows to reduce costs, improves efficiency and management of resources, compliance and risks. It assist to remove all the critical pain points in the traditional supply chain.

Internet of Things (IoT), using the Blockchain technology can improve track-and-trace accuracy and scale the CSC operations. It can also improve inventory management and decrease bank fees such as letter of credit. It can also lead to the creation of Digital Twin.

Investing in Digital Twin Technology

Digital Twin is a virtual model of a real ‘product’, it is connected to the product, updating itself in response to known changes to the product’s state, condition, or context. Companies learn that Digital Twin provides value through visualization, analysis, prediction and optimization. Digital Twin benefits are increase efficiency in manufacturing, optimizes supply chains, transforms predictive field maintenance, aid in traffic congestion remediation and more.

CSC can be notoriously complex, the product can be made of different ingredients and composition. The production line can be layered and multipart. Hence, life cycle information is key to Digital Twins enabling CSC.

When a product has reached its end-of-life and not required by the user, digital twin data guides appropriate end-of-life actions. Data on the operating conditions of specific components inform decisions on whether to re-use, recondition, recycle, or scrap these items. Material data collected can help to determine appropriate recycling and waste streams. The data gathered and stored by the digital twin during this process can be retained for future analysis.

With Digital Twin, companies can anticipate the potential bottlenecks in the supply chain. Companies can make use of Augmented Reality (AR) technology to assist them with machine breakdown. Hence, with these technology tools, companies can minimize the downtime to the lowest extent possible.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Amanda Johnson. (2019). “9 Eco-Friendly Packaging Alternatives for Your Business’s Shipping Needs”. Retrieved from https://greenbusinessbureau.com/blog/8-eco-friendly-packaging-alternatives-for-your-businesss-shipping-needs/, accessed 13/06/2020.

Brianne Ledda. (2019). “DHL Supply Chain launches smart warehouse in Singapore”. Retrieved from https://aircargoworld.com/news/dhl-supply-chain-launches-smart-warehouse-in-singapore/, accessed 17/06/2020.

Commercial Road Transport. (2017). “An adaptable arrangement”. Retrieved from www.primemovermag.com.au/featured/article/an-adaptable-arrangement, accessed 13/06/2020.

Ebro Color. (2020). “Sustainable Packaging: Why Should We Care?”. Retrieved from https://www.ebrocolor.com/sustainable-packaging-report.html, accessed 18/06/2020.

Kuebix. (2019). “How the How the Circular Supply Chain Model Will Replace the Linear Supply Chain”. Retrieved from https://www.supplychain247.com/article/how_the_circular_supply_chain_model_will_replace_the_linear_supply_chain, accessed 13/06/2020.

Lai Wan Voon, ADPSM. (2020). “Three Critical Enablers for Circular Supply Chain”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/three-critical-enablers-circular-supply-chain/, accessed 17/06/2020.

Louis Columbus (2019). “Top 10 Ways Internet Of Things And Blockchain Strengthen Supply Chains”. Retrieved from https://www.forbes.com/sites/louiscolumbus/2019/01/13/top-10-ways-internet-of-things-and-blockchain-strengthen-supply-chains/#2868e1c15e4e, accessed 17/06/2020.

Michelle Lee Ean Wei, ADPSM. (2019). “New Technologies that will Impact Future Supply Chains”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/new-technologies-impact-future-supply-chains/, accessed 17/06/2020.