Throughout shipping, pharmaceuticals are the most vulnerable. Managing security risks in the supply chain during transportation is critical in minimizing potential revenue loss and credibility for producers, distributors, and logistics providers. Training is needed to identify and deter potential pharmaceutical product adulteration or diversion.

Shipping pharmaceutical products requires a high level of knowledge to ensure safe transportation of pharmaceutical products. From the manufacturer to the delivery point, the integrity and value of a pharmaceutical product must be protected. The pharmaceutical industry, like the shipping industry, is working under tight regulations. Know the pharmaceutical shipping rules and get it right every time.

Table of Contents

Cargo Temperature Concerns

The cargo must remain at a certain temperature for the transport of pharmaceuticals in order to maintain their safety and efficacy. Food, particularly frozen foods, and beverages may need to be shipped at a lower temperature than pharmaceuticals, but it is still important to ensure that cargo temperatures are maintained. The exact temperature can range from -58 degrees Fahrenheit to 46 degrees Fahrenheit depending on the pharmaceuticals you are delivering. Such medications could become unsafe to use without proper temperature controls.

The distribution of these drugs through the cold chain is essential to the safe transport. For the shipment of pharmaceuticals, there are two types of cold chain packaging — active and passive.

Active Cold Chain

Active cold chain means the truck has built-in cooling units designed to keep the entire cargo area at a constant temperature. Active cold chain transportation is the better option for temperature-sensitive products like pharmaceuticals.

Refrigerated trucks often called “refers” create a regulated environment within the truck to protect contents against external changes in temperature. Such trailers often have walls sealed, door seals heavy-duty, and even a reflective roof to block the rays of the sun. It prevents the material from rotting, deteriorating, or harming inside.

The quality of Reefer is often perishable. “Perishable” refers to any material that will deteriorate over a period of time if subjected to certain circumstances, according to the International Air Transport Association. Sources include meat, milk, flowers, and tropical live fish. Fine art, flowers, and pharmaceuticals are other types of non-perishable refrigerated shipments.

Passive Cold Chain

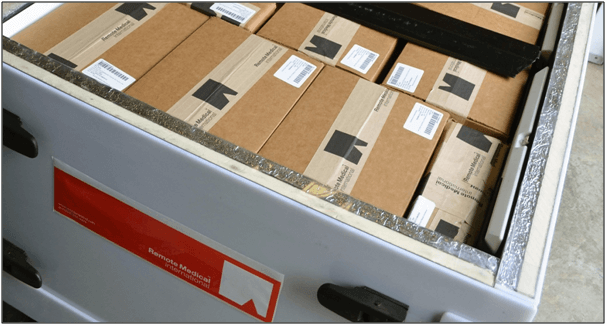

Passive cold chain is what you get when you order meat from the Internet — Styrofoam or polystyrene packaging and ice or dry ice to keep the products cold. The latter presents a problem with pharmaceutical transportation, though — it could allow the products to get too cold or even to freeze, damaging them during transport.

Next Day Air and Refer Shipping Costs

Companies are still using passive cold-chain packaging methods that have weak insulation properties (low R-value). Low R-value packaging solutions such as styrene can only hold temperatures up to 36 hours. This forces companies to use 1-to-2-day shipping options that are becoming costlier as freight, oil, labour and overhead costs increase.

Overnight air shipping rates were 40% to 60% higher than standard land shipping rates. Shipping costs alone can have a significant impact on their bottom line for both cost-conscious and large companies alike. To hold freight costs down, it becomes a constant battle with logistics carriers.

Solution # 1: Lower cold chain quality packaging will move pharmaceuticals, vaccines, biologics, and other temperature-sensitive goods over longer logistics periods.

Temperature Monitoring and Tracking

Atmospheric ambient temperatures change drastically depending on the shipping area during transit in a truck, Ship, Air or some other logistical process.

For example, vaccines begin to lose their efficacy in warm geographic areas such as Phoenix, San Diego, or Orlando within minutes after internal payload temperatures reach the temperature range required. Because of costs and not necessarily required, most specialty pharmaceutical and biological companies do NOT choose to use temperature monitoring systems to track the internal payload temperature of the shipment to ensure it arrives safely at its destination.

The transport sector is a major consumer of energy, heavily dependent on fossil fuels and the production of their prices. Energy scarcity would not only have a significant impact on transportation; the role of transportation in energy consumption makes the sector one of the key starting points for improvements in the energy system and origin transformation.

The need for more fuel-efficient vehicles creates opportunities for innovation, but at a higher cost of capital for suppliers of transport. Several years, leading companies such as UPS and FedEx have been partnering with manufacturers to study delivery vehicles using alternative fuels, including hybrid, liquefied natural gas (LNG) and bio-diesel vehicles.

Telematics in Cold Chain Monitoring

Telematics technology in the management of the cold chain allows fleet managers to gain more control over their cold chain fleets by monitoring the exact location of their vehicles thus enabling their drivers to check the specific temperatures of refrigerated cargo, thereby saving them significant costs.

Through the most dynamic cold chains from processing, refrigerated warehousing, intermodal storage and point of use, personalized cold chain management systems provide a detailed history of consumer temperature. Using telematics, tracking food items and monitoring environmental conditions throughout the entire supply chain is available to the Pharmaceutical industry.

Telematics detectors track the material temperature and humidity. We will determine whether, at any given time, the temperature for a particular food product is above or below the ideal temperature and report the information. This helps companies find locations in a temperature-controlled supply chain–or cold chain–to maintain the quality they like.

Data that Increases ROI

You will boost the fuel savings with real-time data just by seeing where the vehicles can do needless idling or travel around neighborhoods. Improving bad driving practices helps in improved safety and decreases responsibility. Today, realizing that you don’t have to think about injuring your drivers in a collision or destroying your cars, you can sleep better.

System Flexibility

Make sure the process can be customized to your requirements, including incorporation into your current office structures as well as alignment into the office systems of your client. Such kinds of dynamic integrations minimize manual entry for both you and your clients, decrease delays and remove time on the phone to check emails, enabling you to do more work and provide highly differentiated customer service to your rivals.

Better Customer Service

Good customer service is the foundation for any good business. Good customer service should also apply to your supplier of telematics. Whether it’s day or night, if you have any questions or concerns about your plan, you can feel comfortable approaching them.

Conclusion

The shipping of temperature-sensitive pharmaceuticals is in itself a difficult challenge, as both heat and cold must be guarded against the medicines. It is advised that businesses involved in the service of the Pharmaceutical supply chain follow the principle of performance risk management for the purpose of achieving profitability by increasing profits and dismissals due to poor value. Each pharmaceutical organization must establish a quality risk management mechanism during pharmaceutical distribution to achieve the goals of patient safety and customer satisfaction without apprehension of drug regulatory measures due to quality risk.

References

Chill-Pak. (2019). “5 Challenges in Passive Cold Chain Packaging & How to Overcome Them”. Retrieved from https://chill-pak.com/challenges-cold-chain-packaging, accessed 15/12/2019.

Michelle Lee Ean Wei, DLSM. (2018). “Digital Technology for Cold Chain Distribution”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/digital-technology-cold-chain-distribution/#Telematics_in_Cold_Chain_Monitoring, accessed 15/12/2019.

Modality Solutions.(2019). “Why is Pharmaceutical Transportation a Major Concern”. Retrieved from https://www.modality-solutions.com/why-is-pharmaceutical-transportation-a-major-concern, accessed 10/12/2019.

Nichols, M. (2019). “The Top Tips for Safely Transporting Pharmaceuticals”. Retrieved from https://cerasis.com/transporting-pharmaceuticals, accessed 15/12/2019.

Redwood Logistics. (2019). “Refrigerated LTL Shipments”. Retrieved from https://www.redwoodlogistics.com/refrigerated-ltl-shipments-need-know, accessed 15/12/2019.

Vikneswaran Thevar, DLM. (2017). “Key Factors Impacting Transportation Logistics in Supply Chain Management”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-factors-impacting-transportation-logistics-in-supply-chain-management/#Going_Green_Sustainability, accessed 15/12/2019.

Yurista, P., et.al (2019). “5 Reasons to Look into a New Telematics Provider” Retrieved from https://www.assetworks.com/fss-5reasons-telematics-provide, accessed 15/12/2019.