Nowadays, suppliers do not solely have an impact on reducing costs and improving products or services but are more involved in the product design and development process. Hence, selecting the right suppliers and composing the optimal supply base is one of the most challenging parts of strategic purchasing.

Sourcing is a part of the purchasing process that aims at selecting and managing suppliers aligned with strategic organizational goals and objectives. The six sourcing techniques are global Sourcing; Category Management; Portfolio Model; Best Value Procurement; Supplier Selection: and Single versus Multiple Sourcing.

Table of Contents

Global Sourcing

Global sourcing can be identified as seeking for foreign supply sources to include in the overall purchasing strategy. Outsourcing is engaging an outside agency to manage a business function or process of the company. Global sourcing, which is quite similar to offshoring, except that the specialized capabilities are accessed from external agents across geographical borders. The main incentive for outsourcing is cost reduction, especially on labor. However, companies are more exposed to problems due to differences in standards and lack of control.

Nonetheless, experiences and higher quantity production of suppliers can benefit from economies of scale and tapping on capabilities such as expert knowledge, technologies and other resources that are unavailable to the buying company.

Category Management

Category management is defined as a “process for managing entire product categories as strategic business units with a focus on delivering consumer value”. Category management moves away from determining the performance of individual brands and towards the performance of categories of products. It aims to provide a win-win-win situation where suppliers, purchasers, and consumers benefit.

In theory, category management provides opportunities where purchasing and selection of the product meet customer needs. It is believed to achieve cost reduction, effective consumer-oriented practice, helping the company to take a selling perspective and helps in sales-building opportunities as well as addressing strategical issues at the category level.

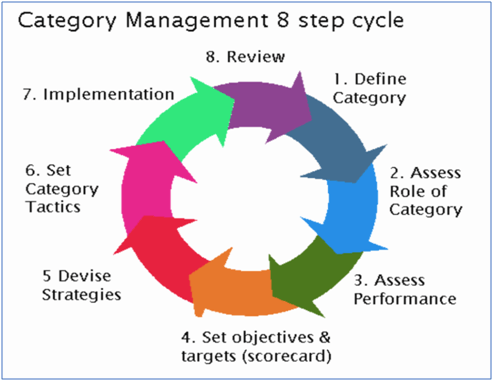

The diagram below shows the 8-step cycle of implementing Category Management.

Portfolio Model

The Portfolio model is a tool that combines two or more dimensions into a set of heterogeneous categories for which different strategies are recommended. With this technique, products and supplier relations can be properly managed. Many kinds of matrices have been developed but the most popular and almost every purchaser knows is the Kraljic matrix.

Kraljic matrix consists of two axes: supply risk and profit impact. These two axes result in four product groups: Routine items, leverage items, bottleneck items, and strategic items – with each differ in the power position between buying company and supplier.

- Routine items are ordered frequently and cause high transactional costs, therefore, the strategic focus is on reducing costs.

- Bottleneck items cause supply problems and the focus should be minimized supply risk.

- Leverage items have a low supply risk and a high-profit impact, therefore, the purchasing company will try to exploit its buying power.

- Strategic items the supply risk and profit impact are high as such, it requires a more collaborative way of purchasing.

Strategic Implementation of Kraljic Matrix

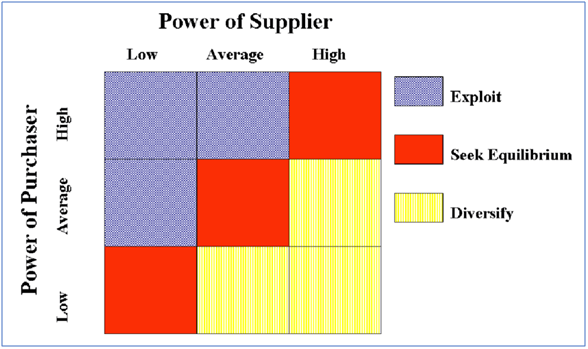

Kraljic’s matrix comes with three strategies: “Exploit”, “Diversify” or “Seek Equilibrium”.

Exploit strategy can be used for the leverage items as there are enough suppliers and the supply risk is low. In this, the buying company is the dominant party, thus they may use an aggressive way to negotiate on the price with the suppliers and sometimes e-auctions can be used. However, a focus on the lowest price will reduce the quality of the products thus buying company should not compromise on this aspect.

Diversify strategy can be used for the bottleneck items as they are known for their high supply risk and low-profit impact. In this case, the supplier is in a dominant position and there is not much room for price negotiation. The focus should be on the supply and less dependency on suppliers. By increasing the stock or having more suppliers ensures the availability of the supply. However, stocking up increases the inventory cost and having more suppliers complex the supply base.

Seek Equilibrium strategy can be used for the routine and strategic items as there is no dominant party.

Routine items have a low-profit impact and a low supply risk. Therefore, it is recommended to have contracts with many suppliers so as to mitigate supply disruption. Strategic items have a high supply risk and high-cost impact to the company due to limited suppliers available, and the willingness of the company to spend huge money on these products, the supplier also cannot risk losing this client. Thus, long-term partnership between buyer and supplier can be considered such as a Joint Research & Development Projects.

Best Value Procurement

In traditional bidding, the price is always the main focus however this approach could trigger suppliers to provide unrealistic low bids which could lead to unwanted economic end-results. Therefore, the Best Value Procurement approach can be considered.

Best value procurement does not solely consider price, but also consider technical criteria and qualifications and claims that to increase the management and performance of the product. The aim is to increase the value added for each monetary unit added, thus to provide an optimal combination of price and performance. Additionally, the risk is shifted to the vendors to show value through their expertise, which then minimizes risk and cost, and providing the best value for the lowest cost.

Supplier Selection

• Sourcing and scouting for supplier

By using a portfolio model, the company knows where the potential supply risk is and therefore may apply the correct decision to source for a supplier. In other words, it is about the decision whether to do a completely new purchase, modified rebuy or straight rebuy.

New purchase refers to a completely new purchase that has not been purchased before and thus needs to walk through the whole purchasing process. This purchase takes time and effort and the chance of uncertainty events are relatively high.

Modified repurchase refers to purchase from an existing supplier or scout for a new supplier or a certain supplier who has transacted before in the past, but decides not to purchase from anymore.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Aastrup, J., Grant, D. B., & Bjerre, M. (2007). “Value creation and category management through retailer-supplier relationships”. Retrieved from: https://www.researchgate.net/publication/247514877_Value_Creation_and_Category_Management_through_Retailer-Supplier_Relationships, accessed 15/03/2019.

Abdelrahman, M., Zayed, T., & Elyamany, A. (2008) “Best-value model based on project-specific characteristics. Journal of construction engineering and management.”Retrieved from: https://www.researchgate.net/publication/238179169_Best-Value_Model_Based_on_Project_Specific_Characteristics, accessed 15/03/2019.

Basuroy, S., Mantrala, M. K., & Walters, R. G. (2001). “The impact of category management on retailer prices and performance: Theory and evidence. Journal of Marketing”. Retrieved from: https://www.researchgate.net/publication/247837072_The_Impact_of_Category_Management_on_Retailer_Prices_and_Performance_Theory_and_Evidence, accessed 15/03/2019.

Burke, G., Carrillo, J., & Vakharia, A. (2007). “Single versus multiple supplier sourcing strategies. European Journal of Operational Research”. Retrieved from: https://pdfs.semanticscholar.org/7cbc/055539e1af0a713041b8c91128d1cc7d40ca.pdf, accessed 15/03/2019.

Caniëls, M. C. J., & Gelderman, C. J. (2005) “Purchasing strategies in the Kraljic matrix – A power and dependence perspective. Journal of Purchasing and Supply Management”. Retrieved from: http://bsidebcn.com/purchasing_strategies_kraljic_matrix.pdf, accessed 15/03/2019.

Choi, T., & Krause, D. (2006) “The supply base and its complexity: implications for transaction costs, risks, responsiveness, and innovation. Journal of Operations Management”. Retrieved from: https://www.researchgate.net/publication/223266168_The_Supply_Base_and_Its_Complexity_Implications_for_Transaction_Costs_Risks_Responsiveness_and_Innovation, accessed 15/03/2019.

Costantino, N., &Pellegrino, R. (2010) “Choosing between single and multiple sourcing based on supplier default risk: A real options approach. Journal of Purchasing & Supply Management”. Retrieved from: https://www.researchgate.net/publication/240167996_Choosing_Between_Single_and_Multiple_Sourcing_Based_on_Supplier_Default_Risk_A_Real_Options_Approach, accessed 15/03/2019.

Lau Chee Leng, DPSM (2018) “Eight Essential Steps for an Effective Global Sourcing Strategy”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/eight-essential-steps-effective-global-sourcing-strategy, accessed 15/03/2019.

Tang Li Xuan, DPSM (2019) “Essential Strategies for Successful Outsourcing”

Retrieved from SIPMM: https://publication.sipmm.edu.sg/essential-strategies-successful-outsourcing/#Supplier_Integrative_Negotiation, accessed 15/03/2019.