Many aspects of the use of time, space, and resources are taken into consideration when designing modern logistic warehouses and distribution centers, making processes more effective through careful planning to increase customer satisfaction and experience.

One of the most important considerations for processing tasks that are dynamically changeable in time and are related to technical and operational structure is optimization. When it comes to optimization implementation, one of the most important factors to consider is safety. However, it is often overlooked inside the warehouse due to negligence or improper standard operating procedures.

Overlooking and failing to enforce safety measures can result in high employee turnover, accidents, legal problems, and even fatalities. This article looks at some of the most common errors made that are crucial for optimizing warehouses.

Table of Contents

Lack of Employees Development and Training

Employers face a number of challenges, including headcount reshuffles and turnover. When an employee leaves a company, there is always a significant cost associated with that departure; it takes a lot of time and effort for the employer to find new employees. Let’s take a look at some of the most common reasons for an employee’s resignation. Poorly trained workers are more likely to feel undervalued at work, leading to an increase in their looking for other opportunities for advancement and growth. In addition to employee retention, poorly trained workers are more likely to make mistakes, lowering quality and increasing inefficiency. They are also more likely to have poor job performance and higher levels of work-related stress. Proper training plans should be used to develop detailed and appropriate training plans for each position, which will be reviewed on a regular basis.

No Management of Obsolete Inventory

End-of-life inventory is inventory that has reached the end of the product life cycle. This stock has not been sold or used in a long time. It consumes valuable warehouse space, increases all carrying costs, and reduces inventory turnover ratios. This type of inventory must be written off, and it can cause a company to suffer substantial losses. Expecting the dead stock to sell as storage costs rise is inefficient. Instead, adopt an inventory reduction strategy to minimize the risk of stockpiling. Make a team of workers responsible for upgrading inventory processes and reducing outdated inventory levels in order to free up storage space for more new or moveable goods.

Overloading the Pallet Racking System

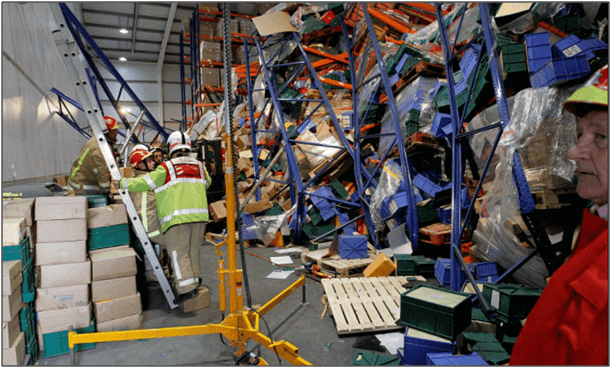

Specific weight limits (SWL) and loading capacity are allocated and designed to withstand the storage capacity, with workplace safety as a top priority. When space is limited or more space is needed during peak periods, it may seem tempting to overstock pallets or overload your racking system with more pallets than recommended. Excessive weight overload can weaken and strain the structures, potentially leading to collapse.

Overruling by stacking pallets too high can result in irreversible damage, resulting in injury or death to employees working in the region. Aside from that, products and processes may be destroyed, resulting in extended downtime. Customers’ dissatisfaction and lack of confidence will undoubtedly have an impact in the future, affecting the company’s profitability and causing unnecessary tensions among stakeholders.

Falling Objects

Stacking items on high platforms and shelves is a common material-handling process. As the height of the racks grow, the risk of falling objects increases. As a result, the material must be properly secured and transported, using stacker trucks or other appropriate tools. When something falls from a great height, it can destroy equipment, injure employees, or even kill them.

These incidents endanger not only employees, but also critical equipment in the potential impact zone. Ascertain that team members are aware of how to stack loads (especially heavy ones) as neatly and securely to prevent them from moving and falling.

Poor Facility Layout with Housekeeping Overlooked

A bad layout will slow down your business. It is also critical to assess warehouse flows correctly and avoid wasting time traveling long distances. Another critical warehousing oversight is failing to consider the importance of creating efficient picking paths through your warehouse. As a result, supply chain cycle times will be affected, resulting in high labour costs due to low productivity.

A hazardous environment and inefficient operation will result from improper warehouse organization. Employees may trip over loose objects on the floor, stairs, and platform due to damaged pallets boards or carton boxes. This type of behaviour does not reflect a positive workplace culture in which workers take pride in their jobs.The risk of slips and falls is increased by spilled liquids, cluttered aisles, boxes, and pallets placed outside of the demarcated area.

For warehouse workers, lifting and moving loads of stock and freight around warehouses and onto trucks is a common occurrence. They often work with material-moving machine operators such as conveyor belt operators and forklift drivers. Physical exertion is a requirement of the work. Accidents can happen to warehouse workers in a variety of ways.

- Slipped or herniated discs

- Wrist and hand injuries

- Injuries caused by repetitive motion

- Cuts, bruising, and abrasions

- Broken bones

- Injuries to the spinal cord

- Burns/ Scarring

Accidents will result in lost man-hours and unnecessary commotion, all of which will have an impact on the process. Warehouse safety and efficiency go hand in hand, housekeeping should be a routine after every shift or completion of any scope of work. Effective and proper housekeeping can help to remove risks and provide a better working environment for employees.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Apcgroup, (2019). “The Effects of Overloading Your Pallet Racking System”. Retrieved from https://www.apcgroup.com.au/news/2019/the-effects-of-overloading-your-pallet-racking-system, accessed 20/03/2021.

David Chew Kian Peng, DLSM (2018).”Four Keys Area for Mitigating Warehouse Risks”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/four-key-areas-mitigating-warehouse-risks/, accessed 20/03/2021

Jack Faizal Bin Sulaiman, DLSM (2020). “Key Consideration for Co-Warehousing Spaces”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-considerations-co-warehousing-spaces/, accessed 20/03/2021.

Tracey Baker, (2020). “Obsolete inventory management: the causes and cures”. Retrieved from: https://www.eazystock.com/uk/blog-uk/obsolete-inventory-management-causes-solutions/#Causes_of_obsolete_inventory, accessed 20/03/2021.

Zhang Zhong Wei, DLSM (2019). “Major Consideration for Chemical Warehousing”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/major-considerations-chemical-warehousing/, accessed 20/03/2021.