As we know, technology is an ever-evolving and ever-influential part of our everyday lives – and it’s advancing so quickly that it can be difficult to predict what is coming next. This sentiment is particularly true regarding the fields of warehousing. If you purchase, or influence purchases, within your operation, you’ve been well aware of the emergence of the “smart warehouse.” Once regarded as a buzzword, or even a far-fetched pipe dream, the smart warehouse is becoming a reality, backed by ready-to-purchase technologies that are changing the way warehouses do business. An effective warehouse must be appropriate for the materials being stored. Likewise, a sound understanding of the inventory is necessary to create an efficient and successful operation and below we will briefly explain the warehouse technology.

Table of Contents

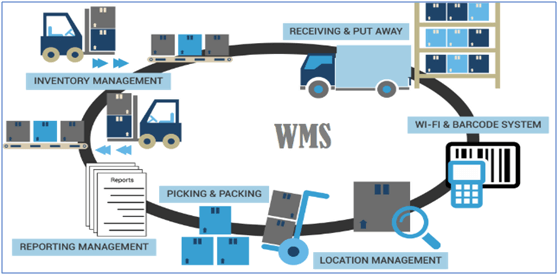

Warehouse Management System

A warehouse management system (WMS) is a software application, designed to support and optimize warehouse functionality and distribution center management. These systems facilitate management in their daily planning, organizing, staffing, directing, and controlling the utilization of available resources, to move and store materials into, within, and out of a warehouse. A warehouse management system usually represents the central unit in the software structure of a warehouse. The WMS receives orders from the overlying host system, mostly an ERP system, manages these in a database and, after appropriate optimization, supplies them to the connected conveyor control systems. In the process, WMS has made many warehouse activities faster for people to perform and generated efficiencies to reduce labor-intensiveness.

Barcode System Use on the Pharmaceutical Sector

A barcode is an image consisting of a series of parallel black and white lines that, when scanned, relay information about a product. Barcodes are read by optical devices such as a barcode reader or scanner.

Pharmacode (also known as Pharmaceutical Binary Code) is a one-dimensional (1D) barcode used all over the world. It is a specific type barcode standard used mainly in pharmaceutical manufacturing. Pharmacode barcode is used for Online Security Control of the pharmaceutical packaging process. You can find the Pharmacode barcode on the packaging of any pharmaceutical products, usually, it is on the outside of the packaging containing the medicine. The purpose of this barcode is not generally like the Code39 barcode and Code128 barcode. Due to its importance, it is designed to be error proof and to provide the encoded information despite printing mistakes.

Paperless Order Picking and Packing System

Most companies begin with manual piece picking, however, as they grow they find that this strategy cannot accommodate high volume in the warehouse. Looking at zone, batch and wave picking, along with some level of automation is a logical progression to support future growth and efficiency. In a pick-to-light system, an operator will scan a bar-coded label attached to a box. A digital display located in front of the picking bin will inform the operator of the item and quantity that they need to pick.

Companies usually use pick-to-light systems for their top 5 to 20% selling products. This system help companies can gain significant efficiencies as it is totally paperless and eliminates the errors caused by pick tickets. Voice picking system informs the operator of pick instructions through a headset. The pick instructions are sent via RF from the company’s ERP or order management software. The system allows operators to perform pick operations without looking at a computer screen or deal with paper pick tickets. World Class warehouse operations have adopted voice picking to complement the pick-to-light systems in place for their fast-moving products.

Radio Frequency Identification (RFID)

Radio frequency identification (RFID) system has been successfully applied to the areas of manufacturing, supply chain, agriculture, transportation, healthcare, and services. The RFID is already used to track and trace the victims in a disaster situation. Data can be collected in real time and be immediately available to emergency personnel and saves time by the RFID.

The RFID systems work much like any other radio frequency system. The receiving antenna picks up a signal in the form of radio waves from an object that is sending out the signals. In identification systems, the transponder is an RFID tag that communicates with the antenna and the equipment that decodes the information. Because of the reduced size and the remarkable technology, such an ID tag can be programmed and used for long periods of time. If a person carrying or wearing an RFID tag approaches a building or other location where the antenna is in place the signal is received by the antenna. With an active tag, the person does not have to be as close as he or she would with a passive tag. Active tags have an additional power source. Even if the RFID tag is inside clothing or otherwise covered it may be “read” by the receiving equipment. This identification, based on information on the tag, happens in much less than a second. Several tags approaching the receiving station can be “read” and identified at almost the same time. This is one of the keys to protecting retail stores and other businesses. RFID tags can be attached to products to prevent shoplifting. These tags have to be deactivated by store personnel so you can leave the store without setting off the alarm. One of the problems that government and rescuers are facing is to identify and follow victims after saving them under debris after earthquake occurrence. Recording, storing, and retrieving victims’ data in information systems can provide useful information to supply:

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Ann Chong Fong Ting, DPSM.(2018). “Warehouse Technologies for Effective Inventory Conan trol”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/warehouse-technologies-effective-inventory-control, accessed on 19/03/2019.

Bathe tool Akbari1, Sima Ajami2.(2015). “Radio frequency identification and rescue victims in earthquake” Retrieved from: http://www.ijhsdm.org/article.asp?issn=2347-9019;year=2015;volume=3;issue=5;spage=1;epage=5;aulast=Akbari,accessed on 19/03/2019.

Eddie Kek Chun Beng, DLSM. (2018). “Techniques to Improve TAT for Warehouse Operations”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/techniques-improve-tat-warehouse-operations, accessed on 19/03/2019.

Eric Bohn, Magdalena Krapf.(2019). “Fundamentals of GMP Warehouse Design”. Retrieved from http://www.pharmtech.com/fundamentals-gmp-warehouse-design, accessed on 19/03/2019.

Jean Lim Yoon Chin, DLSM.(2018). “Techniques of Order Picking for Warehouse Productivity”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/techniques-order-picking-warehouse-productivity, accessed on 19/03/2019.

Peternikolow. (2013). “Pharmacode – Pharmaceutical Barcode”. Retrieved from:

http://www.mobiliodevelopment.com/pharmacode-pharmaceutical-barcodecode/#gref, accessed on 19/03/2019.

Shelly Stazzone.(2019). “7 Smart Warehouse Technologies to Implement Today”. Retrieved from https://www.camcode.com/asset-tags/smart-warehouse-technologies, accessed on 19/03/2019.

Westfalia Technologies, (2018). “Pharmaceutical Industry Automated Storage Solutions” Retrieved from https://www.westfaliausa.com/solutions/pharmaceutical,accessed on 19/03/2019.