Having sustainable procurement in building industry as the acquisition of product or services which can minimize or provide positive environmental impact throughout the factoring of environmental concerns into major purchasing strategies, policies, directives and practices. Sustainable procurement is the integration of requirements, specifications and criteria that are friendly to the environment.

A quieter part of the sustainability story is that the evolution in techniques of construct and materials procuring which will reduce waste, energy and various inefficiencies at building sites. However, sustainable procurement play an important role in achieving Leadership in Energy and Environmental Design (LEED).

Table of Contents

Prefabricating Modular

The approach of prefabricated modular has been garnering an increasing amount of attention in the building industry. A building’s large scale modularized component is prefabricated offsite in a controlled environment and deliver the final product for quick assembly onsite.

This due to the interrelated issues of rising costs of traditional construction practices, the shortage of skilled construction workers and the increase of demand. Prefabricated Construction offers cheaper and less time consuming to erect compare to traditional construction methods, yet it also bring sustainable benefits as well. Building Information Management (BIM) systems have been use by contractors to perform metal cutting where materials can be cut precisely and decrease waste.

Offsite prefabrication in the controlled environment are often able to achieve higher standard of quality than site built where the raw materials are left exposed to the weather to extend period of time. Hence, contribute to a more climate-responsible future by offering solutions with a significantly lesser environmental impact than other forms of building. Common claims for sustainability from prefabricating modular are include reduced of material waste, reduced operational energy, safer working environment and reduced disruption to the building site and the surrounding community. Most part of the prefabricated modular are constructed with recycled and recyclable materials. Recycled concrete, steel, wood even glass are the large part of what makes up a modular building. In fact, not every part this building can be made from recyclable materials, but all of these part undoubtedly can be reused over and over again without seeing much wear and tear.

Waste Management

Minimization of construction waste is becoming more achievable by contractors as hauliers have grown into more sophisticated and varied in recent years. Up to 80% of construction wastes are recyclable. A system must put in place where recyclables are placed into separated bins at the jobsite and sorted onside. Generally, this is more cost effective than commingled and recycling rates can be as high as 90% or higher. Contractors shall engage with authorized collector for the collection and removal or disposal of waste generated. All building debris shall be dispose at site directed by authority. As such, by recycling waste materials are not only help to alleviate the waste disposal issues and but at the same time provide an alternative to natural resources and landfill avoidance through recycling.

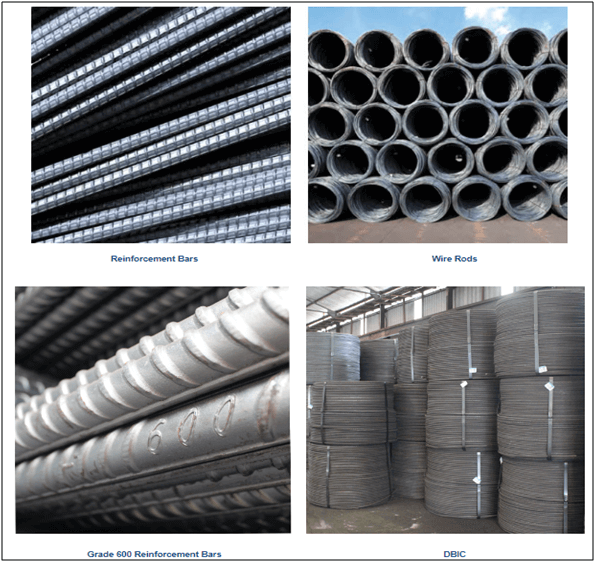

Recycling of metal scraps is one the most effective recycling recoveries. These Metal scrap will undergo stringent radiation check and this is to ensure the delivery of premium and high quality reinforcement steel solutions that are sustainable and safe. The proper and effective recycled metal into new product, it is embodied lower energy and make the material more sustainable since it is not extracting from raw material. Basically this is cut out the whole raw material extraction and processing, if you think from the whole cycle from extracting raw material to the processing to the installation to the demolition and disposal.

Lean Thinking Principle

Integrating lean thinking principle into green building has been remarkable and practitioners have been shown increasing interest in this principle. Many of contractors have been adopted this principle because of itself valuable benefits to the project as whole. Implementation of this approach have reported morbidity results. This principle is used to maximize the economic benefits, address quality, waste reduction and minimize the negative environmental impacts in green building. In green building, lean construction is the management process on production that involves site staff and getting the workers not waiting for works and works are not waiting for workers, which is suffering by social disturbance. There are several benefits from implement lean thinking principle such as improved quality and delivery performance, fewer defects and rework, fewer machine and process breakdowns, lower level inventory, less space required, higher efficiency, faster development, greater customer satisfaction, improved supplier relations and increased business.

Green building industry is encouraged to adopt lean principle thinking as a muscular approach to increase its efficiency, effectiveness and eliminating waste. In addition, green building is adopted to enhance health, improving building performance, useful life and reuse or recycle of materials and principally to minimize impact on environment. As a result, it can be presumed that lean leads to green, but is not necessarily vice versa, which is reiterated and confirmed. However, the fields of lean and green have been developed largely independent of each other.

The principles of lean technique are:

- Kaizen – It is a continuous improvement strategy that improve work process in a various way which making things better.

- 5S System – As in Sort, Set in order, Shine, Standardize and Sustain. A framework to create and maintain the workplace with the purpose is to reduce wasteful time and motion at micron level.

- Poka-Yoke – Also known as “Mistake Proofing”, using wide variety of ingenious device to prevent occurrence of mistakes or defects.

- Kaban – The purpose is to schedule production and minimizing work in progress while motivating improvement in many areas.

- Just In Time – It is a production strategy that attempt to improve a business Return on Investment (ROI) by minimize in-process inventory and associated carrying costs. Goods received only as needed for the production process.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Chua Seok Khim, DPSM. (2019). “Crucial Techniques to Control Construction Inventory”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/crucial-techniques-control-construction-inventory/, accessed 24/06/2020.

Construction Pros. (2020). “5 Techniques for Sustainable Building Construction“. Retrieved from https://www.forconstructionpros.com/business/article/12068798/five-techniques-for-sustainable-building-construction, accessed 19/06/2020.

David Cartwright. (2018). “Sustainable Construction: Techniques and Trends”. Retrieved from https://www.buildsoft.com.au/blog/sustainable-construction-techniques-and-trends, accessed 19/06/2020.

Greg Dick. (2018). “Green Building Materials”. Retrieved from https://www.calrecycle.ca.gov/greenbuilding/materials, accessed 24/06/2020.

James Wilson. (2019). “The Potential of Prefab: How Modular Construction Can Be Green”. Retrieved from https://www.buildinggreen.com/feature/potential-prefab-how-modular-construction-can-be-green, accessed 24/06/2019.

Master of Project Academy. (2020). “The 8 Essential LEAN Techniques You Need to Know”. Retrieved from https://blog.masterofproject.com/8-lean-techniques/, accessed 27/06/2020.

Mohammad Naeem, ADLSM. (2019). “Lean Six Sigma Best Practices for Effective Supply Chain”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/lean-six-sigma-best-practices-effective-supply-chain/, accessed 27/06/2020.

Serene KeQuanling, DPSM. (2020). “Key Considerations for Green Procurement Practices”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-considerations-green-procurement-practices/, accessed 19/06/2020.

Siti Noridah Supaat, DPSM. (2019). “Essential Sustainable Practices for Procurement of Mineral Products”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/essential-sustainable-practices-procurement-mineral-products/, accessed 19/06/2020.